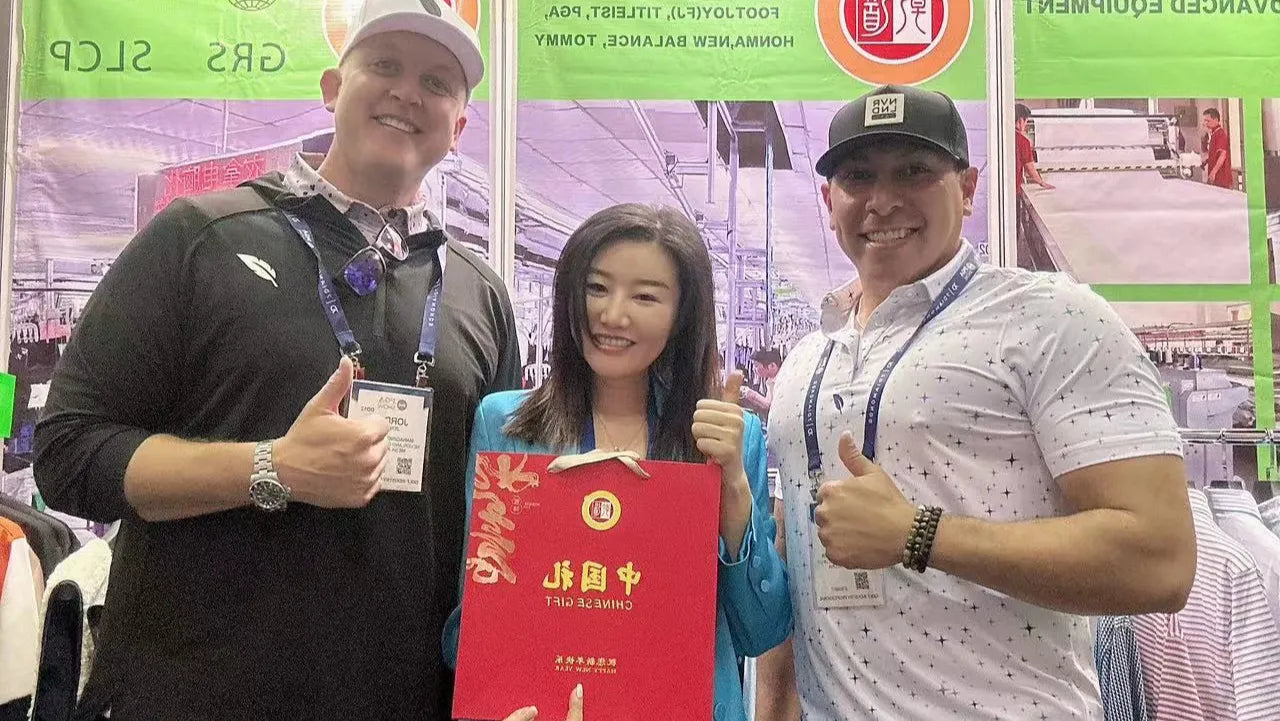

OUR MAJOR CUSTOMERS

Scaling Dreams with Small Batches

A Startup’s 120-Piece Launch

Client Background: Nordic Tee is a young golf apparel brand based in Sweden, founded just two years ago. Their vision is to merge Nordic minimalism with high-performance golfwear. As a startup, they wanted to test the market with smaller orders to control inventory and cash flow. Which is hard to achieve. Challenge: Their previous suppliers required 500–1000 pcs per style, which was far beyond what a startup could handle.Nordic Tee only needed 120 pcs per designto launch their pilot collection.They also needed fast sampling to validate their designs before committing to production.

Scaling Dreams with Small Batches

Solution & Clients' Feedback

Solution: Qiandao Apparel provided a flexible MOQ program that supports orders starting from 100 pcs (mixed sizes), matching perfectly with the client’s request for 120 units. Light Design + physical pre-production samples ensured quick approvals. Dedicated supported fabric sourcing, trims, and finishing technical adjustments in real time. Risk of over-stocking was minimized, helping the brand enter the market confidently. Client Feedback: “We placed an order for only 120 pieces and got the exact flexibility we needed. The samples came quickly, and production quality exceeded expectations. We could finally test the market without the financial burden of a huge MOQ.”— Astrid L., Founder of Nordic Tee

From Flaws to Finesse

Elevating Quality with Every Stitch

Client Background: Southern Links is a long-established golf apparel supplier in the U.S. South, serving private clubs and league teams. Their clients are detail-oriented and often request last-minute modifications. Improper design timelines increased risk. Challenge: Previous suppliers failed to maintain consistent quality, with issues such as fabric shrinkage and stitching defects.The brand needed the ability to tweak colors, fit, and trims during production.Sample lead times were long, delaying approvals and slowing product launches.

From Flaws to Finesse — Elevating Quality with Every Stitch

Solution & Clients' Feedback

Solution: Qiandao Apparel set up a Brand Elevation Program tailored to Southern Links: Premium processes like laser cutting, DTG printing, and embroidery ensured high consistency. Access to 200+ certified fabrics and Pantone-matched colors enabled quick customization. A dedicated components lab supported 24-hour turnaround for design revisions and new samples. Client Feedback: “The consistency in fabric and finishing has been outstanding. Whenever we requested changes, the team responded within a day and delivered updated samples quickly. It has really strengthened our brand reputation.”— Kelly M., Brand Manager at Southern Links

Beating the Clock

Delivering Golfwear Right on Tournament Time

Client Background: Green Edge Sports is a Swiss distributor that supplies golf apparel to premium country clubs across Europe. Their seasonal business model requires precise delivery schedules for spring and autumn launches. This requires strict time control. Challenge: In the past, late deliveries (up to 2 weeks delay) caused serious issues for club tournaments.Tight seasonal windows meant missing delivery dates directly impacted sales.They also needed flexibility in adjusting SKUs during production, but most factories couldn’t accommodate changes once production had started.

Beating the Clock — Delivering Golfwear Right on Tournament Time

Solution & Clients' Feedback

Solution: Qiandao Apparel created an integrated production & logistics plan:Tech pack development with 3D prototyping enabled faster approvals. Make sure full transparency at every stage. A cross-timezone support team coordinated last-minute adjustments and ensured logistics aligned with club schedules. Client Feedback: “This season, everything arrived one week earlier than planned. The communication was transparent, and we had the flexibility to adjust SKUs without losing time. Our country club clients were delighted.”— Marc R., Purchasing Manager at GreenEdge Sports:

Light Custom Design

We support brands by refining every design detail—from label placement and logo color coordination to fabric selection and functional trims. Whether you're launching a new line or optimizing a best-seller, we’re here to make every piece more you.

FROM SKETCH TO PRODUCTION

If you have a product concept and plan, we can help you evaluate and optimize the solution and create a prototype. Once you confirm the prototype meets your needs, we can turn the concept into reality, mass-produce it, and bring it to market.

Commentary Excerpts

Qiandao Apparel made our custom golfwear project effortless. The team was responsive to every detail, from fabric selection to last-minute adjustments. Our first order of 120 pieces was delivered right on schedule, and the quality exceeded our expectations. It truly felt like having a reliable partner by our side.” — David Thompson, Founder of Fairway Golf Co. (UK)

See More Ccooperation CasesMANUFACTUER AUTHORIZATION

ISO9001

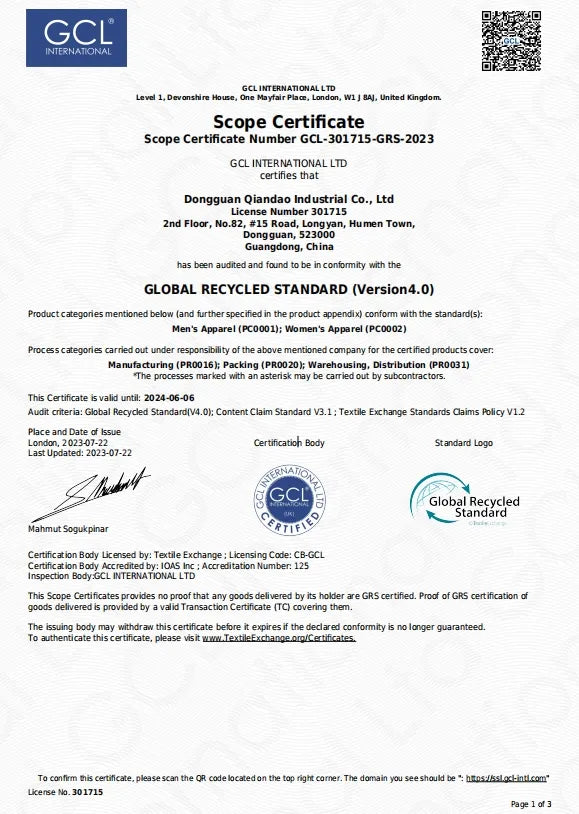

GRS

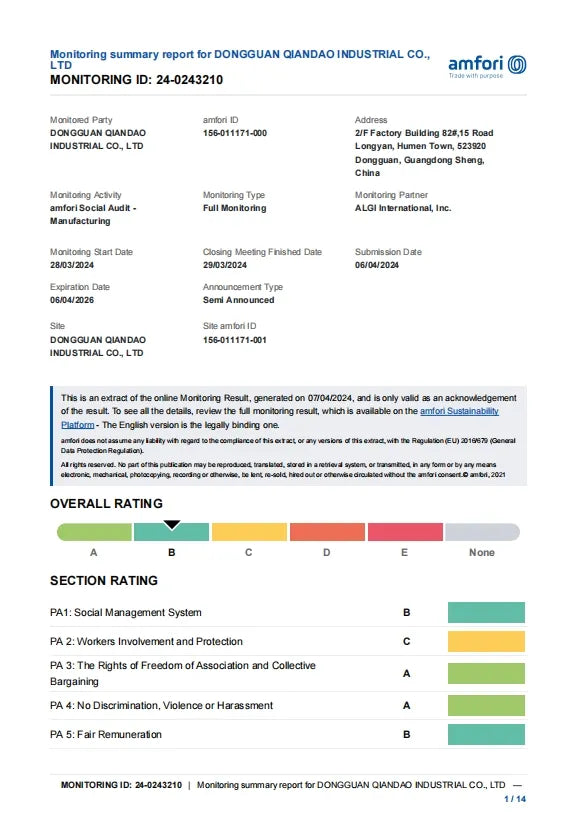

BSCI

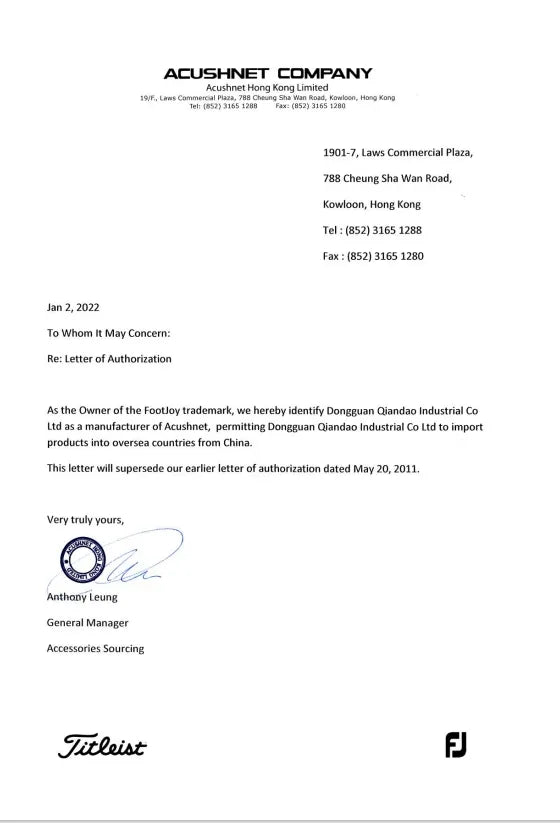

FJ

PGA

NB

Ready to Build Your Custom Golfwear Story?

Digital Infrared Thermometer

$49.50Best Electronic Digital Thermometer adipiscing elit, sed do eiusmod teincididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse us ultrices gravidaes.

- Category: Medical Equipment

- Brand: Medical Equipment