How to Distinguish Knitted and Woven Fabrics?

How to Distinguish Knitted and Woven Fabrics?

Understanding and differentiating the weaving principles and characteristics of knitted and woven fabrics to produce appropriate garments based on their distinct properties.

Fabrics can be classified in three ways:

-

By composition: For example, 90% wool, 85% polyester, etc., as typically labeled on clothing tags.

-

By fabric structure: Such as plain weave, twill weave, jacquard, etc.

-

By weaving method: Divided into knitted and woven fabrics.

This article will differentiate fabric types based on weaving methods and structures. Knitted and woven fabrics have unique characteristics in terms of weaving techniques, processing methods, fabric structure, properties, and applications. Neither is superior; the choice depends on selecting the appropriate fabric for its intended use.

I. Weaving Methods: Knitting & Weaving

Knitted Fabrics:

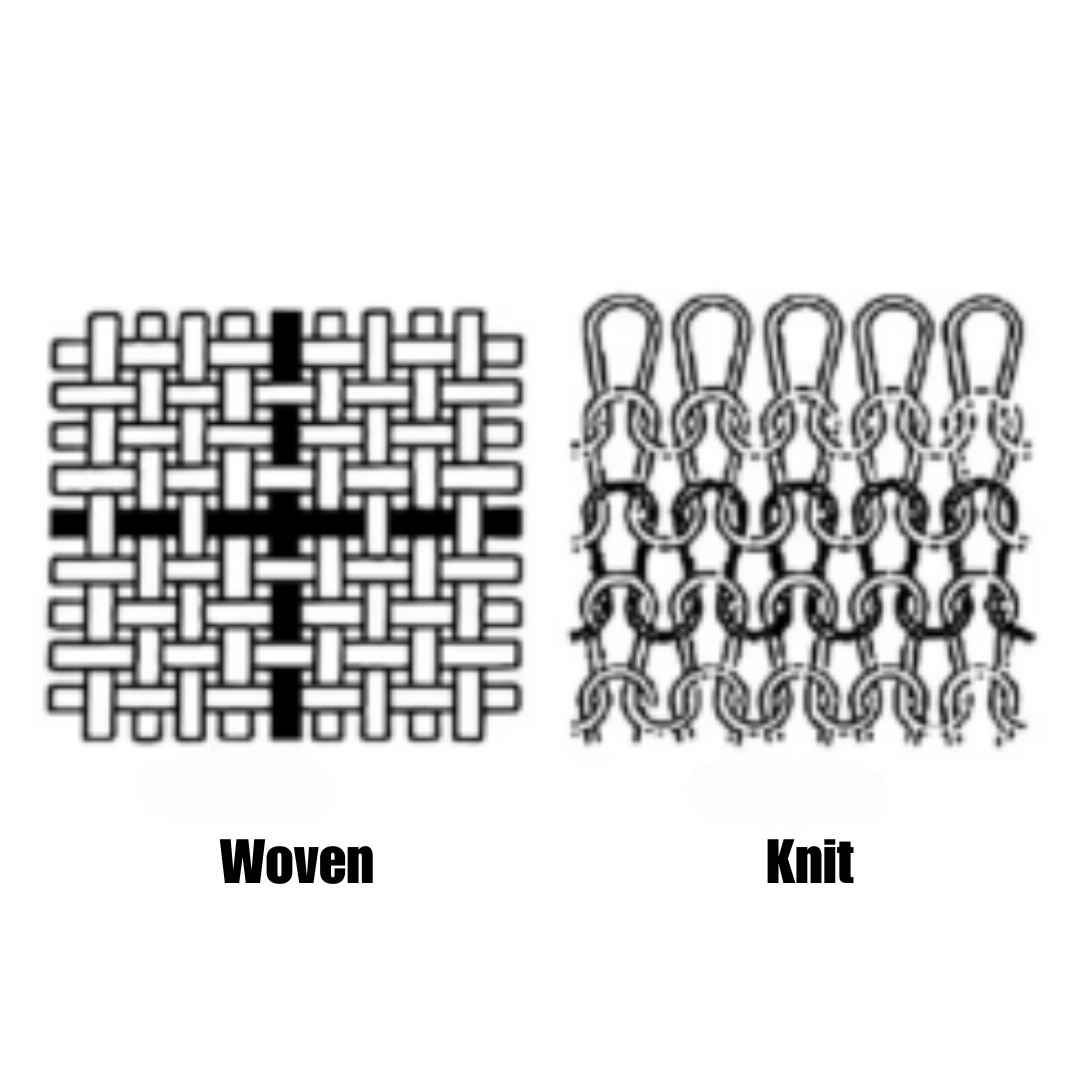

Knitting is a process where needles form yarn into loops, which are then interconnected to create fabric. It can be done horizontally (weft knitting) or vertically (warp knitting).

-

Loops are the smallest fundamental unit of knitted fabrics, composed of a "loop trunk" and an "extension line" forming a spatial curve.

Woven Fabrics:

Woven fabrics are created by interlacing two or more sets of mutually perpendicular yarns at a 90-degree angle. The vertical yarns are called warp yarns, and the horizontal ones are weft yarns. Their primary structures include plain weave, twill weave, and satin weave.

-

The intersection points between warp and weft yarns are called binding points, the smallest fundamental unit of woven fabrics.

(Tip: While knitted fabrics are generally elastic and woven fabrics are not, this is not absolute. Woven fabrics can exhibit elasticity if made with elastic yarns.)

II. Fabric Structures Under Knitting and Weaving

[Knitting]

Knitted fabrics have specific structural classifications:

A. Weft-Knitted Fabrics: Plain stitch, rib stitch, purl stitch, terry fabric, jacquard fabric, pique, etc.

B. Warp-Knitted Fabrics: Tricot fabric, satinet fabric, chain stitch fabric, etc.

-

Plain Stitch

-

The simplest structure, formed by continuous single-direction loops. It has high horizontal stretch but tends to curl and unravel.

-

Used for T-shirts, underwear, sportswear, and lightweight summer garments.

-

Rib Stitch

-

Combines rows of face loops and reverse loops. Offers excellent elasticity.

-

Used for cuffs, collars, hems, and stretchable clothing like underwear.

-

Purl Stitch (Double Reverse Stitch)

-

Alternates face and reverse loop rows, creating a pebbled texture. Balanced vertical/horizontal stretch.

-

Common in sweaters, sportswear, and children’s garments.

-

Terry Fabric

-

Features raised loops on one or both sides for softness and absorbency.

-

Used for towels, bathrobes, sportswear, and leisurewear.

-

Jacquard Fabric

-

Forms intricate patterns by selectively skipping stitches. Decorative and luxurious.

-

Applied in high-end dresses, home décor (curtains, upholstery), and artistic textiles.

-

Pique (Lacoste Fabric)

-

Combines plain stitches and raised "pearl" structures for a honeycomb-like surface. Breathable and durable.

-

Ideal for polo shirts, sportswear, and performance apparel.

-

Tricot Fabric

-

Basic warp-knitted structure with alternating loop directions. Lightweight and semi-elastic.

-

Used for swimwear, lingerie, and lightweight garments.

-

Satinet Fabric

-

Features smooth, silk-like surfaces with diagonal textures. Soft and drapes well.

-

Suited for elegant dresses, scarves, and formalwear.

-

Mesh Fabric

-

Contains regular openwork holes for breathability. Adjustable hole sizes and densities.

-

Used in sportswear, bridal wear, and mosquito nets.

[Weaving]

Woven fabrics are categorized into three primary structures and their derivatives:

-

Plain Weave: Simplest structure with a 1/1 interlacing pattern.

-

Twill Weave: Diagonal lines formed by continuous warp/weft floats.

-

Satin Weave: Long floats create a lustrous, smooth surface.

III. Characteristics

Knitted Fabrics:

-

Elasticity: High elasticity and extensibility due to loop structure.

-

Texture: Soft, flexible, and skin-friendly.

(Knitted fabrics entered high fashion via Coco Chanel, who popularized them in her early designs.)

-

Breathability: Excellent airflow, suitable for active and casual wear.

-

Applications: T-shirts, sportswear, lingerie, and form-fitting garments.

Woven Fabrics:

-

Structure: Tight, rigid, and less deformable.

-

Texture: Crisp and structured, requiring tailored designs for fit.

(Madeleine Vionnet pioneered the bias-cut technique to enhance woven fabric elasticity, though it increases material waste and is mainly used in bespoke tailoring.)

-

Breathability: Less breathable, often used for formal or indoor apparel.

-

Applications: Shirts, suits, formalwear, and structured garments.

Ⅳ. Quick Identification of Knits & Wovens-- Stretch

Knitted fabrics are generally soft and flexible. When stretched, they expand bidirectionally, with coarsened textures, widened gaps, and visible deformation. They rebound and restore their original form upon release.

Woven fabrics exhibit a crisp and structured handfeel. Their morphological structure remains largely unchanged during stretching, demonstrating minimal deformation.

Leave a comment

Your email address will not be published.